ODM / OEM

Best Effort for

a Cup of Happiness, CUPFUL

Product Development Process

01

Receive OEM order (Outsourcing)

Upon receipt of OEM order from a customer with certain specifications, we start product development

02

R&D for OEM Product

R&D focuses on potential ingredients to meet best the customer’s requirements

03

Labeling

Once the ingredients are confirmed, we put full ingredient labeling on the back of the package.

06

Payment

Sub-division and casing work to be invoiced, separately. Cost of food inspection, etc. to be invoiced separately, as actual expenses.

05

Processing

Outsourcing of product sub-division for number of small batches (Cost to be invoiced). Customers can work on it of their own.

04

Package Design (Including printing)

Partial outsourcing/ Subcontracting the design/ Design by ourselves Inquire about product development

Product subdivision and packaging stage

Product Subdivision & Packaging

01

Receive packaging order

Upon receipt of a packaging order from a customer, we start the process planning.

02

Discuss about the processing steps

Discuss the shape and forma of packaging and confirm the requirements with the customer.

03

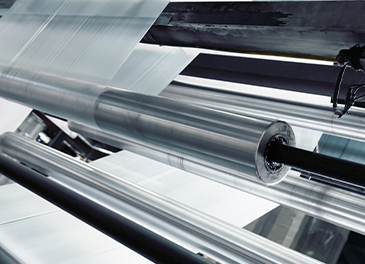

Check the package material

Check the package material and discuss about post-processing requirements

05

Payment

Subdivision and casing work to be invoiced, separately. Cost of food inspection, etc. to be invoiced separately, as actual expenses

04

Processing

Proceed with product subdivision and packaging, finish work with casing, and complete the post-processing requirements